Overview

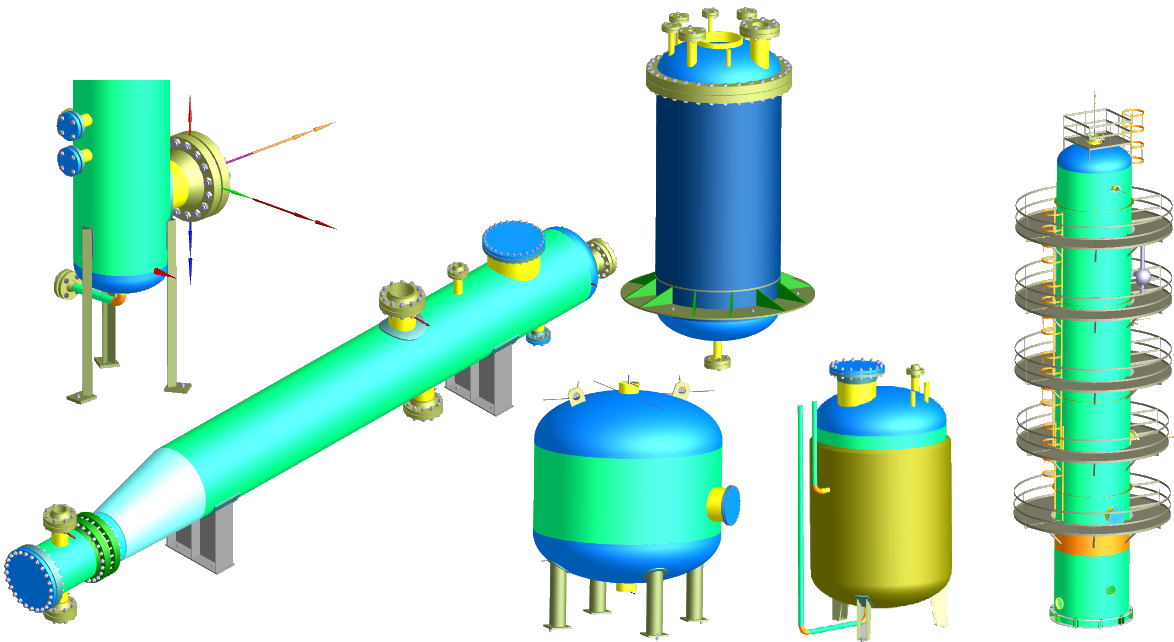

PASS/EQUIP software provides pressure vessel strength and stability analysis for horizontal and vertical vessels, columns, storage tanks, as well as shell-and-tube, and air cooled heat exchangers under static and seismic loads in order to evaluate bearing strength in operation, test, and assembly states. The software can be used for designing, revamping and testing of vessels, as well as for code compliance certification calculations for power, oil-refining, chemical, petrochemical, natural gas, petroleum, and other related industries. PASS/EQUIP helps to increase reliability and operational safety of equipment for various applications, to improve coordination of the project with regulatory authorities, and to reduce costs and time.

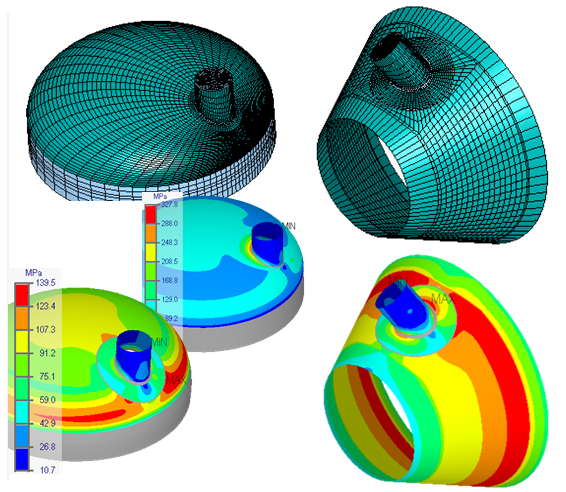

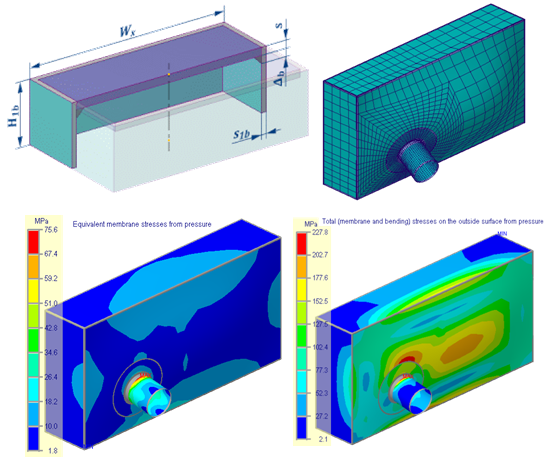

PASS/EQUIP FEM bundle additionally provides stress and flexibility FEM analysis of arbitrary vessel nozzles, including allowable loads calculation.

PASS/EQUIP combines sophisticated calculation capabilities and code compliance analysis with ease-of-use, delivering pressure vessels stress and stability simulation tool to even entry level engineers and designers. Detailed calculation reports produced by the program contain comprehensive information (including all equations, intermediate results, plots of forces and moments) and are ready for delivery to any authorities or equipment certification bodies.

Equipment designers and process and piping engineers of more than 500 EPC and vessel manufacturing companies in Belarus, China, Czech Republic, Estonia, France, Germany, India, Italy, Japan, Kazakhstan, Latvia, Poland, Russia, South Korea, Spain, Ukraine, Uzbekistan and USA now use the software every day for design of different types of vessels, columns, tanks, and heat exchangers.

Due to the large number of users and feedback from specialists of different industries, PASS/EQUIP continues to steadily evolve to meet modern demands. PASS/EQUIP is being permanently verified and cross-tested both vs similar programs and Example Problem Manuals ASME PTB-3-2013 and ASME PTB-4-2012.

PASS/EQUIP has a modern intuitive user interface, detailed documentation and help system, and provides the ultimate in usability, allowing users to focus on equipment design. A user defines an equipment type, geometrical adjectives, material of vessel components, type and allocation of supports, test type, and loading rates. The vast databases for vessel elements and materials are delivered with the program and can be updated by the user.

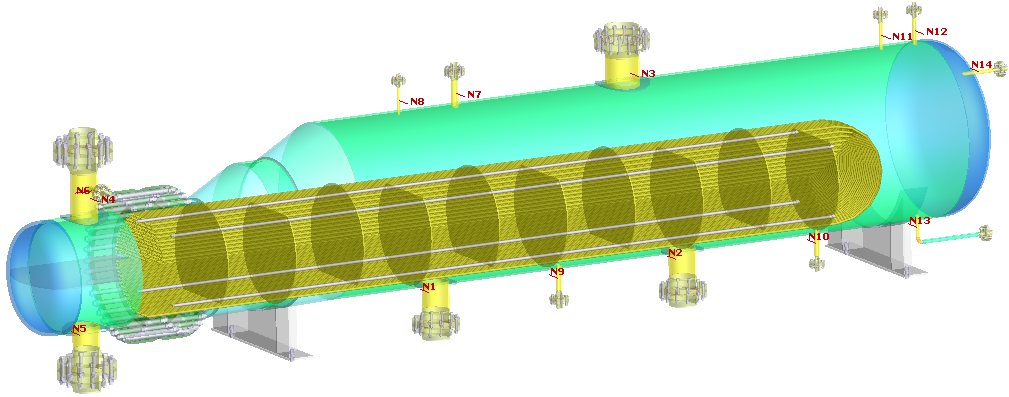

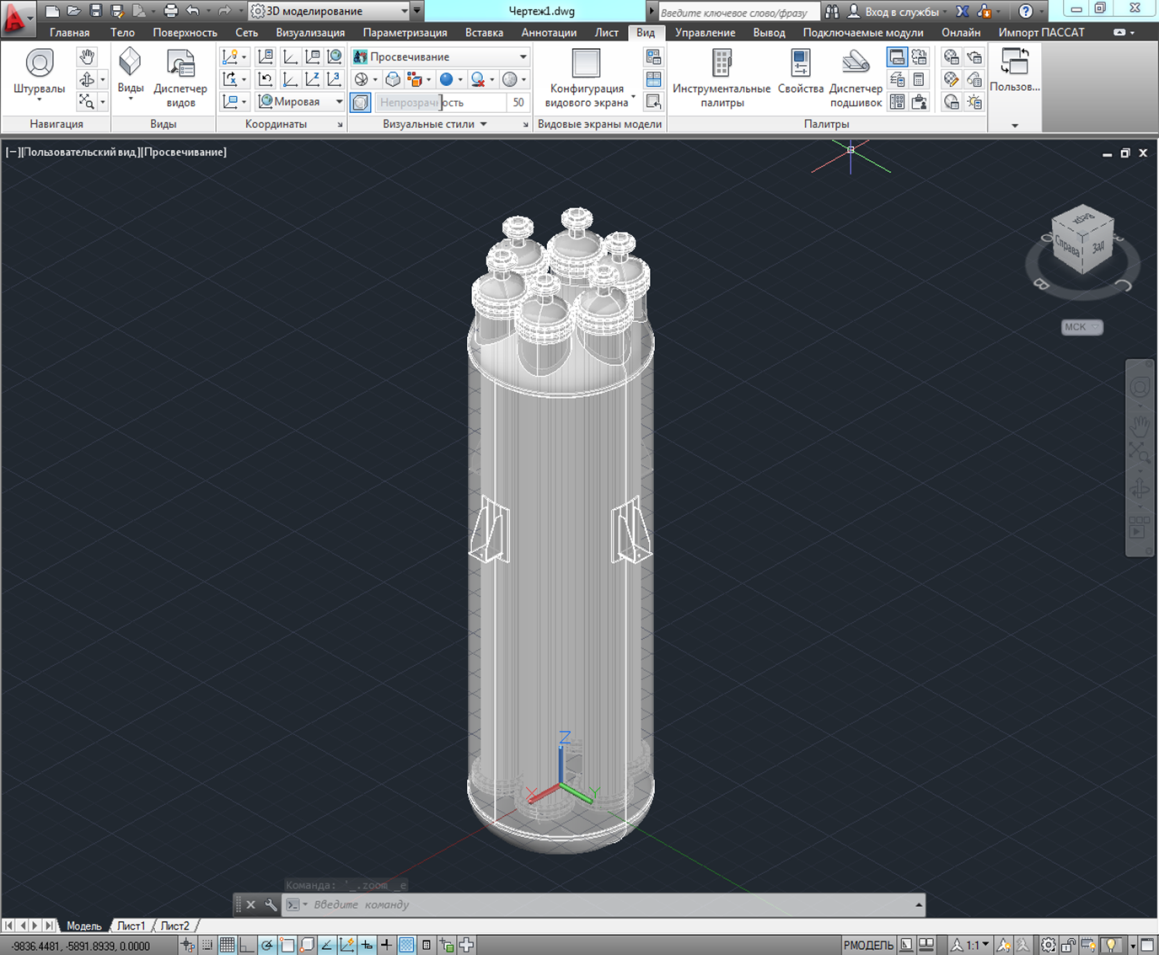

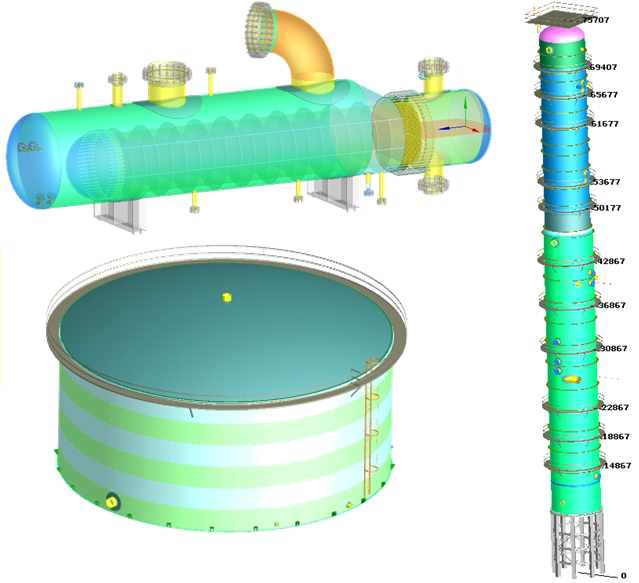

3D graphic view of equipment geometry allows editing color of separate elements or of the whole model, with internal elements views. Powerful 3D modeling capabilities also support export to various CAD formats, so users can continue working on vessel design in their favorite CAD systems.

PASS/EQUIP does not require a special training and can be used by any mechanical engineer. New users can get pressure vessel analysis results in days rather than months!

Our specialists provide timely technical support.

Powerful capabilities

PASS/EQUIP provides comprehensive structural pressure vessels analysis.

PASS/EQUIP performs strength and stability calculation of horizontal, vertical, and column vessels, and takes into account wind and seismic loads. PASS/EQUIP also calculates strength and stability of shell and tube heat exchangers, including tubesheets, tubes, pass partitions, shells, expansion bellows, expansion boxes, and floating heads. The smart tube grid editor of heat exchanger provides very powerful capabilities of non-standard tubesheets modeling.

The program performs calculation of strength and stability of pressure vessels according to the most popular codes. PASS/EQUIP supports ASME Standards (Sec.VIII div.1 and div.2), European Standards (EN 13445-3), WRC 107(537)/297, GOST Standards (34233.1-12) and others.

The program allows to calculate nozzles in rectangular walls.

Calculation of the skirt supports of columns (cylindrical, conical, composite), weakened by the hole is available.

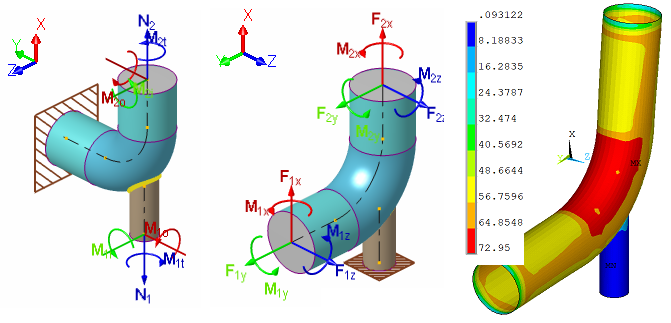

PASS/Nozzle-FEM allows to calculate pipeline elements – such as tees, bend stanchion, oblique tie-ins.

User Interface

PASS/EQUIP has a modern, clear and intuitive user interface. Designer uses 3D object-oriented analysis model of equipment assembled from different elements. The objects that make up the equipment 3D model are:

- Cylindrical shells (smooth and reinforced with stiffening rings);

- Conical transitions;

- Welded bottoms and detachable bottoms and covers (spherical, elliptical, torispherical, conical, flat (including with stiffeners), spherical non-flanged);

- Flange connections;

- Places of connections of fittings;

- Saddle supports and cylindrical shells in the places of their support in the case of horizontal vessels and apparatus;

- Cylindrical shells, conical elements and convex bottoms at the points of attachment of the bearing lugs, lifting trunnions, at the points of attachment of metal structures;

- Reinforcement of holes;

- Bends;

- Tie-in (choke) in shells and convex bottoms;

- Elliptical partitions;

- Ellipsoidal transitions;

- Elements of column-type apparatus against wind and seismic effects, including those installed on a pedestal;

- Supporting shells of column-type apparatus;

- Tube sheets, casing, pipes, compensator, expander, floating head of heat exchangers;

- Chambers of heat exchangers for air cooling;

- Elements of vessels and apparatus with jackets (cylindrical, U-shaped, partially covered by jackets, with coil and register channels, with longitudinal channels);

- Elements of vessels and high-pressure apparatus (shells, bottoms, flanges, covers, tie-ins);

- Elements of vertical tanks;

- Viewing windows, bosses.

System Requirements

Codes

Calculation codes

- API 650-2020. Welded Tanks for Oil Storage.

- ASME VIII, Div 1. Rules for construction of pressure vessels.

- ASME VIII, Div 2. Rules for construction of pressure vessels. Alternative rules.

- EN 13445-3. European Standard. Unfired pressure vessels – Part 3. Issue 1 (2002-05).

- WRC-537 (107) Welding Research Council. Bulletin. “Precision Equations and Enhanced diagrams for Local Stresses in Spherical and Cylindrical Shells due to External Loadings for implementation of WRC Bulletin 107. 2013.

- WRC-297 Welding Research Council. Bulletin. “Local Stresses in Cylindrical Shells due to External Loadings on Nozzles – Supplement to WRC Bulletin №107”. 1987.

- WRC-368 Welding Research Council. Bulletin. “Stresses in Intersecting Cylinders subjected to Pressure”. 1991.

- Bildy, Les M., 2000, “A Proposed Method for Finding Stress and Allowable Pressure in Cylinders with Radial Nozzles,” PVP Vol. 399, ASME, New York, NY, pp. 77-82.

- Zick, L.P., “Stresses in Large Horizontal Cylindrical Pressure Vessels on Two Saddle Supports”, Welding Research Journal Supplement, September, 1951.

- Henry H.Bednar, Pressure Vessel Design Handbook. Second edition. 1986.

- Dennis R.Moss, Pressure Vessel Design Manual. 1987.

- AzDTN 2.3-1. Seysmik rayonlarda tikinti (zərbaycan Respublikası Dövlət Şəhərsalma və Arxitektura Komitəsi).

- IS 1893. Indian Standard. Criteria for earthquake resistant design of structures.

- GOST 34233 (1-12) - 2017. Vessels and equipment. Norms and methods of strength calculation.

- GOST 34283-2017. Vessels and equipment. Vessels and Equipment. Norms and methods of strength calculation from wind loads, seismic influence and other external loads.

- GOST 14249-89. Vessels and apparatuses. Norms and methods of strength calculation.

- GOST 25221-82. Vessels and equipment. Spherical heads and covers without knuckle. Norms and methods of strength calculation.

- GOST 26202-84. Vessels and equipment. Norms and methods of calculation for strength of shells and heads against support loads.

- GOST 24755-89. Vessels and equipment. Norms and methods of strength calculation of holes reinforcement.

- RD 26-15-88. Vessels and equipment. Norms and methods of strength and leak integrity calculation of flange joints.

- RD RTM 26-01-96- 83. Flat round heads and heads with radial reinforcing ribs of vessels and equipment.

- RD 10-249-98 Norms of strength calculation of stationary boilers and steam and hot-water pipelines.

- RD RTM 26-01-44-78. Details of pipelines for pressure over 10 to 100 MPa. Norms and methods of strength calculation.

- PNAE G-7-002-86. Strength calculation norms of the equipment and pipelines of atomic power plants.

- OST 26-01-64-83. Fasteners. Construction and dimensions.

Databases

In order not to enter the necessary settings manually, there are a number of embedded databases:

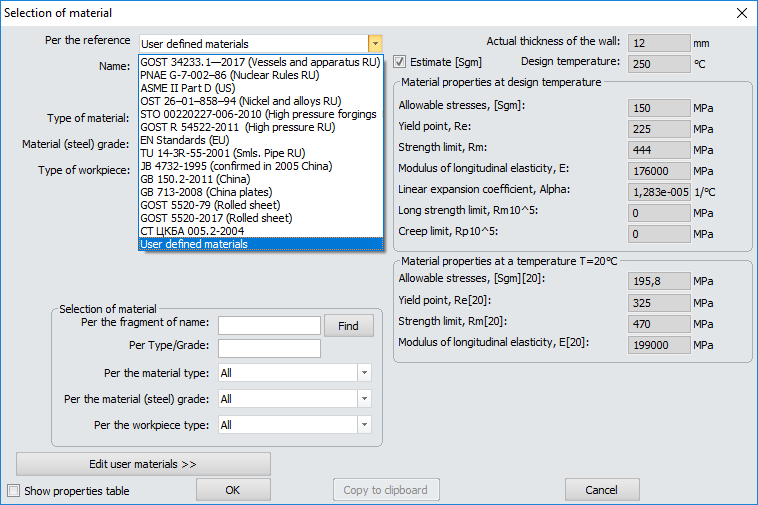

Materials

The database contains physical materials properties from the most popular codes:

- ASME II Part D-2017 (US)

- EN Standards (EU)

- JB 4732-1995 (confirmed in 2005 China)

- GB 713-2008 (Chinese plates)

- GB 150.2-2011 (China)

- GOST 34233.1—2017 (Vessels and equipment RU)

- PNAE G-7-002–86 (Nuclear Rules RU)

- API 650-2020 (Oil tanks US)

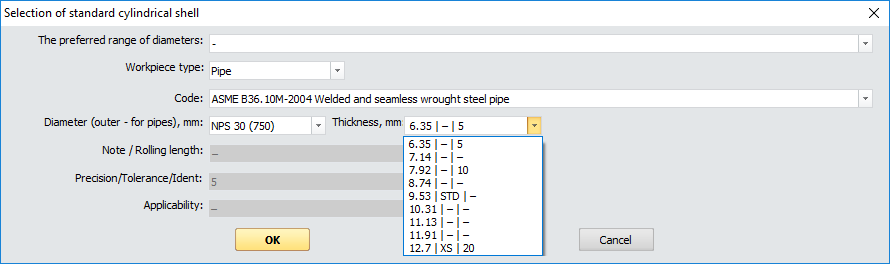

Sheets, pipes and standard shapes

The database is aimed to specify size of fittings and pipe fittings side of standard sheets and pipes according to ASME, EN, Russian codes with automatic definition of negative tolerance:

- ASME B36.10M-2004 (Welded and seamless wrought steel pipe)

- EN 10055:1995 (Hot rolled steel equal flange tees)

- EN 10056-1:2017 (Structural steel equal leg angle)

- EN 10058:2018 (Hot Rolled Flat bar)

- EN 10058:2018 (Hot Rolled Wide Flat)

- EN 10059:2003 (Hot rolled square bar for general purposes)

- EN 10060:2003 (Hot rolled round bar for general purposes)

- EN 10210-2:2019 (Hot finished Circular hollow sections)

- EN 10210-2:2019 (Hot finished Rectangular hollow sections)

- EN 10216-1:2002 (Seamless steel tubes for pressure purposes - Technical delivery conditions)

- EN 10365:2017 (Taper flange U channels CH type)

- EN 10216-1:2002 (Seamless steel tubes for pressure purposes - Technical delivery conditions)

- EN 10253-2-2007 (Butt-welding pipe fittings. Non alloy and ferritic alloy steels with specific inspection requirements)

- ASME B1.1-2003 (Unified inch screw threads)

- ISO 68-1:1998 (ISO general purpose screw threads)

- SA-480/SA-480M (Specification for general requirements for flat-rolled stainless and heatresisting steel plate, sheet, and strip)

- ASME B16.48-2015 (Line Blanks)

- ASME B16.9-2018 (LR) (Elbows)

- ASME B16.9-2018 (SR) (Elbows)

- ASME B16.9-2018 (Elbows 3D)

Stiffening rings

Flanges

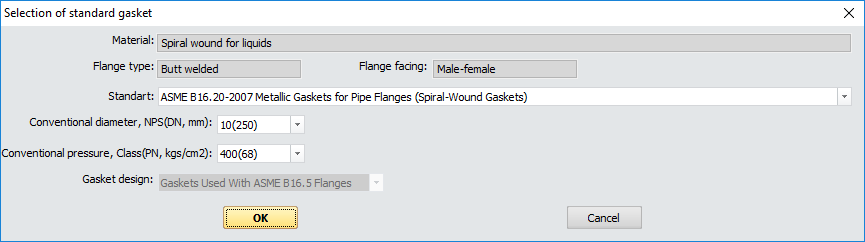

The database contains all necessary dimensions and specifications of flanges, bolts (studs) and gaskets for ASME, EN, Russian codes:

- ASME B16.5-2009 (Pipe Flanges and Flanged Fittings)

- ASME B16.47-2006 (Large Diameter Steel Flanges)

- EN 1092-1 (Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories, PN designated)

- GOST 33259-2015 (Flanges for valves, fittings and pipelines for nominal pressures up to PN 250. Design, dimensions and general technical requirements)

- GOST 28759.1-90 (Flanges of vessels and apparatus. Types and sizes)

Supports

Configurations

PASS/EQUIP can be delivered in different configurations:

PASS/Equipment Vessel

PASS/Equipment Vessel provides stress analysis for vessels and columns.

PASS/Equipment Vessel&Exchanger

PASS/Equipment Vessel&Exchanger provides stress analysis for vessels, columns and heat exchangers.

PASS/Equipment Tank

PASS/Equipment Tank provides stress analysis for vessels and tanks.

PASS/EQUIP can be also delivered as a bundle with PASS/Nozzle-FEM:

PASS/EQUIP FEM Vessel

PASS/EQUIP FEM Vessel is a bundle that provides stress analysis for vessels, columns and nozzles.

PASS/EQUIP FEM Vessel&Exchanger

PASS/EQUIP FEM Vessl&Exchanger is a bundle that provides stress analysis for vessels, columns, heat exchangers, and nozzles.

PASS/EQUIP FEM Tank

PASS/EQUIP FEM Tank is a bundle that provides stress analysis for vessels, tanks, and nozzles.

PASS/EQUIP FEM Complete

PASS/EQUIP FEM Complete is a bundle that provides comprehensive design by rules and design by FEM analysis. Includes Vessel, Column, Exchanger, Tank & Nozzle analysis.

Download Software

| Software | Link | Upload Date |

|---|---|---|

| PASS/EQUIP 3.7.0.0 (English) | request |

11.07.2024 |

| PASS/EQUIP 3.6.0.15 (English) | request |

08.07.2024 |

| LMS (Sentinel HL and Guardant) Tools (only for PASS/NOZZLE-FEM 3.5, PASS/HYDROSYSTEM 4.6 and PASS/EQUIP 3.7) | ||

| Dongle Update Tool (KeySt) for Guardant and Sentinel HL | zip, 16.76 MiB | 09.07.2024 |

| Drivers and network key manager for Sentinel HL dongles (Windows) | exe, 37.14 MiB | 12.12.2023 |

| Drivers for Guardant dongles | exe, 11.43 MiB | 24.12.2021 |

| SuperPro Tools | ||

| Dongle Update (KeySt) | zip, 4.13 MiB | 13.12.2023 |

| Dongle Drivers SafeNet Sentinel 7.6.9 | exe, 7.37 MiB | 13.12.2023 |